01

DX53D DX55D Galvanized Coil

Galvanised steel coils are widely used in the following industries:

In the construction industry: to manufacture structural elements low-rise construction, light steel thin-walled structures, sandwich panels, lining of heat pipelines and various heat insulation, conditioning systems, metal roof shingle, profiled sheeting, culvert pipes, cladding of entry doors, elevators, reinforcement profiles for PVC windows and plastic doors, European-type fasteners for plasterboards, etc

| Q/BQB 420-2003 | EN 10142:2000 | EN 10142:1990 | JISG3302-1994 | ASTMA653M-2002 |

| EN 10147:2000 | EN 10147:1991 | |||

| EN 10292:2000 | ||||

| DC51D+Z(St01Z, St02Z, St03Z), DC51D+ZF | DX51D+Z, +ZF | FeP02GZ, ZF | SGCC | CS Type C |

| SGHC | ||||

| DC52D+Z(St04Z) DC52D+ZF | DX52D+Z, +ZF | FeP03GZ, ZF | SGCD1 | CS Type A, Type B |

| DC53D+Z(St05Z) DC53D+ZF | DX53D+Z, +ZF | FeP05GZ, ZF | SGCD2 | FS Type A, Type B |

| SGCD3 | ||||

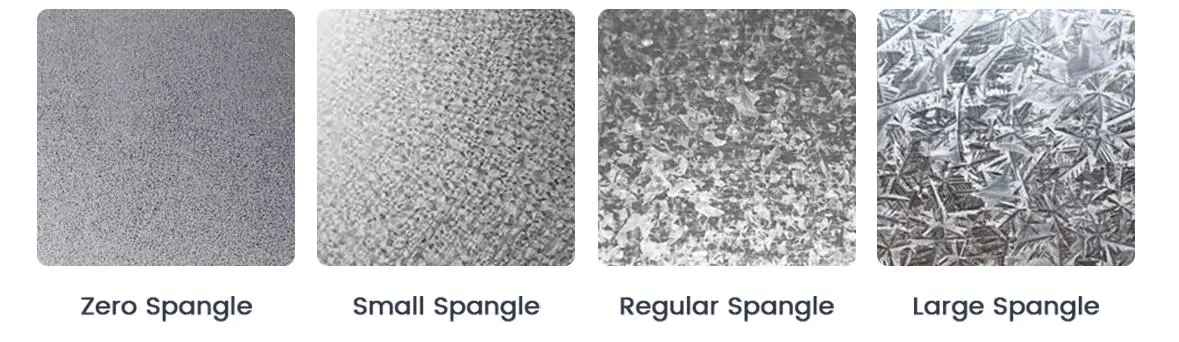

| Distinguish | Surface and Appearance Requirements | |||

| Home appliances | Micro-wave oven(L/S), home appliance side panels, etc. | Use smooth small spangle or zero spangle hot-dip galvanized steel strip, and the defects that must not exist include rust, corrosion, perforation, delamination, serious head-up lines, impact damage, fold marks, serious edge burrs, large waves, Intensive periodic concave and convex points, obvious zinc slag, zinc spot, galvanized line, zinc layer falling off | ||

| Appliance door panels (T/R, H/G)wait | Use zero-spangle hot-dip galvanized steel strip, and the defects that must not exist include rust, corrosion, perforation, delamination, severe head-up lines, impact damage, fold marks, serious edge burrs, large waves, and dense periodic bumps. , Obvious zinc slag, zinc spot, galvanized line, zinc layer peeling off | |||

| Architecture | Building exterior decoration (C/S) | Use smooth small spangle or zero spangle hot-dip galvanized steel strip, and the defects that must not exist include rust, corrosion, perforation, delamination, serious head-up lines, impact damage, fold marks, serious edge burrs, large waves, Intensive periodic concave and convex points, obvious zinc slag, zinc spot, galvanized line, zinc layer falling off. To some extent, the surface roughness is allowed to be slightly larger | ||