Products

Zinc Ingot Factory Direct Sales

Shandong Rigang Supply Chain Management Co.,Ltd Zinc ingot refers to pure zinc, and of course there will be impurities, but as zinc ingot, it has at least 90% purity. The use of zinc ingots: mainly used in die-casting alloys, battery industry, printing and dyeing industry, pharmaceutical industry, rubber industry, chemical industry, etc. Alloys of zinc and other metals are widely used in electroplating, spraying and other industries. Zinc alloy die castings are used in automobile, light industry and other industries. The processing performance of many zinc alloys is relatively good, and the pass processing rate can reach 60%-80%. Excellent medium pressure performance, can be deep drawn, and has self-lubricating properties, which prolongs the life of the mold. It can be welded by brazing, resistance welding or arc welding (need to be in helium), and the surface can be electroplated and painted. Good cutting performance. It has superior superplastic properties under certain conditions.

Lead Ingot Factory Direct Sales

Shandong Rigang Supply Chain Management Co.,Ltd Lead ingots are rectangular, with protruding ears at both ends, blue-white metal, and soft. The density is 11.34g/cm3, and the melting point is 327°C. Lead ingots are divided into large ingots and small ingots. Among them, the small ingot has a rectangular trapezoidal shape, with bundling grooves at the bottom, and protruding ears at both ends; the large ingot is trapezoidal, with T-shaped bumps at the bottom, and grabbing grooves on both sides. Lead ingots are mainly used in the manufacture of batteries, paints, warheads, welding materials, chemical lead salts, cable sheaths, bearing materials, caulking materials, Babbitt alloys and X-ray protective materials, etc.

From the perspective of the industrial chain, the upstream of lead ingots is lead ore and lead concentrate; the midstream is the manufacturing and processing of lead ingots, including lead oxide, lead alloys, lead plates, etc., and the downstream is the application fields of chemical industry, cables, batteries and radioactive protection.

Factory Reinforcing Welded Wire Fence Mesh

Shandong Rigang Supply Chain Management Co.,Ltd.Welded mesh alias: touch welded mesh, row welded mesh, welding protective mesh

Size: 1/2" 1/4" 3/4" 3/8" 5/8" 1" 2" 3" 4"

Material: high quality medium and low carbon steel wire, stainless steel wire. Welding: Welding first and then plating, first plating and then welding.

Process: butt welding, row welding.

Anti-corrosion treatment: electro-galvanizing, hot-dip galvanizing, PVC coating, PE dipping, epoxy resin, etc.

Performance: It has strong anti-corrosion and anti-oxidation, bright surface color, and strong color selection.

Uses: Welded wire mesh is often used in poultry cages, egg baskets; fences in airports, gutters, porches, etc.; protective nets for machines and shelves for planting and animal protection. Welded mesh is often used for building exterior wall insulation, wall hanging nets, etc.

High Tensile Wire Prestressed steel wire

Shandong Rigang Supply Chain Management Co.,Ltd. Prestressed steel wire is a high-strength steel, widely used in construction, bridges, tunnels, water conservancy projects and other fields. It has excellent mechanical properties and durability, and can effectively improve the bearing capacity and seismic performance of structures.

The material of the prestressed steel wire is mainly high-strength steel wire, and steel wires such as SWRH82B and SWRH77B are usually used. These steel wires have the characteristics of high strength, high toughness, high durability, etc., can withstand large tensile and bending forces, and also have good corrosion resistance and fatigue resistance.

The manufacturing process of prestressed steel wire mainly includes drawing, steel wire stranding, prestressing processing and other links. During the drawing process, the steel wire is drawn and annealed multiple times to make it meet the requirements of high strength and high toughness. In the wire stranding process, multiple steel wires are twisted into one prestressed steel wire to improve its bearing capacity and seismic performance. During the prestressing process, the prestressed steel wire is tensioned to a certain level of prestressing, so that it generates compressive stress in the structure, thereby improving the bearing capacity and seismic performance of the structure.

Magnesium Ingot Factory Direct Sales

Shandong Rigang Supply Chain Management Co.,Ltd Magnesium ingot is a new type of lightweight corrosion-resistant metal material developed in the 20th century. It is mainly used in four major fields: magnesium alloy production, aluminum alloy production, steelmaking desulfurization, and aviation and military industry. As one of the metal structural materials with the lowest density, magnesium alloy is widely used in aerospace industry, military field, transportation field (including automobile industry, aircraft industry, motorcycle industry, bicycle industry, etc.), 3C field, etc. The characteristics of magnesium alloy can meet the requirements of high-tech fields such as aerospace for noise absorption, shock absorption, and radiation protection of lightweight materials, and can greatly improve the aerodynamic performance of aircraft and significantly reduce structural weight.

Aluminum Ingot Factory Direct Sales

Shandong Rigang Supply Chain Management Co.,Ltd Aluminum, our daily industrial raw material is called aluminum ingot, which should be called "aluminum ingot for remelting" according to the standard, but everyone is used to calling it "aluminum ingot". It is produced by electrolysis using alumina-cryolite. Unwrought product. The product obtained by smelting (or refining) and casting. For example, rolled ingots, extruded ingots, forged ingots and aluminum ingots for remelting.Product specifications and materials can be customized according to customer requirements.

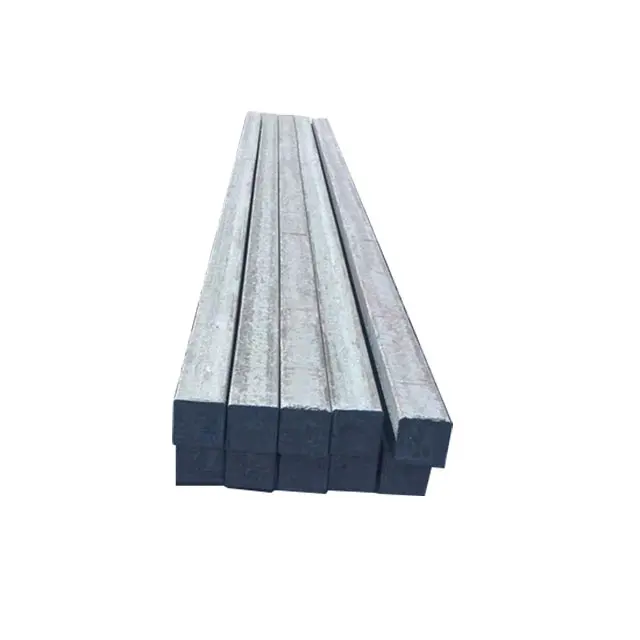

China Factory Direct Sales Mill Produced Steel Billet

Shandong Rigang Supply Chain Management Co.,Ltd steel billet are classified according to the chemical composition of steel: non-alloy steel billets, low-alloy steel billets, and alloy steel billets. Steel types mainly include: plain carbon steel, high-quality carbon structural steel, low-alloy high-strength structural steel, high-quality ribbed steel, hot-rolled special-shaped steel for coal machinery, structural steel for hull, alloy structural steel, and steel wire for welding Steel, spring steel, mining steel, cold heading steel, carbon and alloy steel for boilers, steel for pressure vessels, steel for seamless gas cylinders, steel for bridges, light rail steel, steel for automobile girders, steel for welding bottles, There are more than 180 kinds of 23 series of pipeline steel, container plate steel, weather-resistant steel and composite substrate steel.

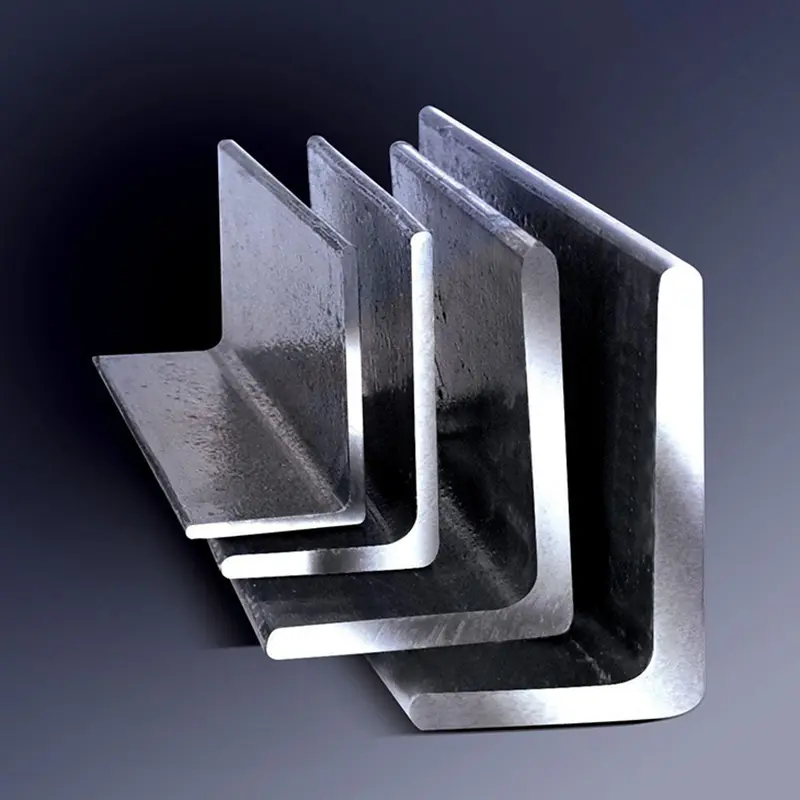

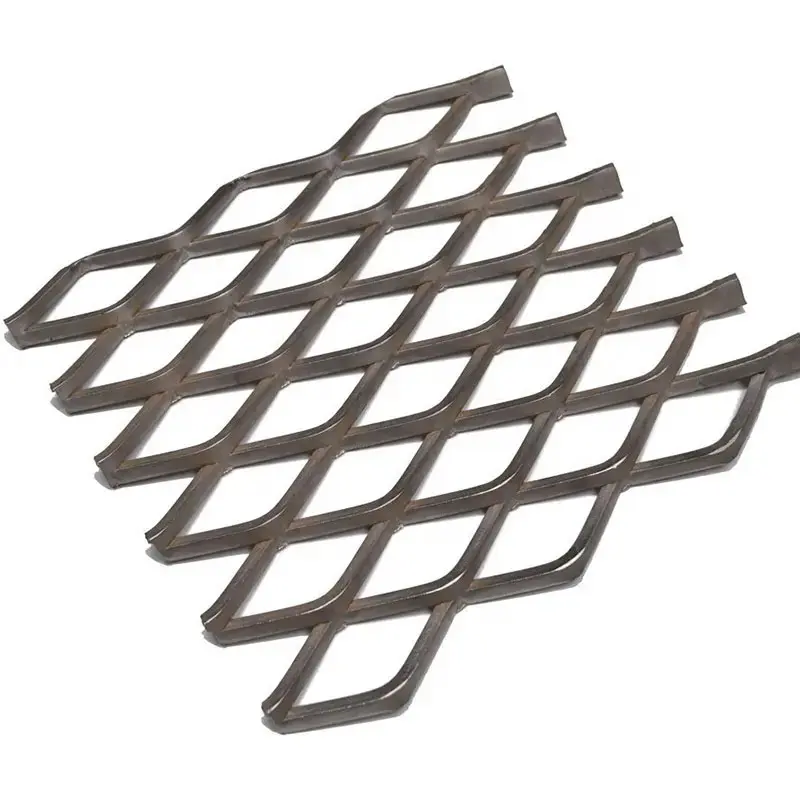

Factory Aluminium Decorative Expanded Metal Mesh

Shandong Rigang Supply Chain Management Co.,Ltd. Metal sheet stretched mesh also refers to steel sheet stretched mesh, metal punching and shearing mesh. The stretched metal net refers to the metal plate net with different image holes formed by punching, shearing and stretching the metal plate. Common materials are steel plate, aluminum plate, stainless steel plate, brass expanded mesh, nickel expanded mesh, etc.

Types of stretched metal mesh: perforated stretched metal mesh, heavy duty stretched metal mesh, medium stretched metal mesh, light stretched metal mesh, galvanized stretched metal mesh, tortoise shell stretched metal mesh Mesh, plastic-coated metal sheet stretched mesh, filter element metal sheet stretched mesh, stainless steel sheet metal stretched mesh, diamond-shaped metal sheet stretched mesh, steel fence mesh, dipped metal sheet stretched mesh, aluminum sheet metal stretched mesh , Steel corner mesh, hexagonal metal sheet stretched mesh, copper sheet metal stretched mesh, etc.

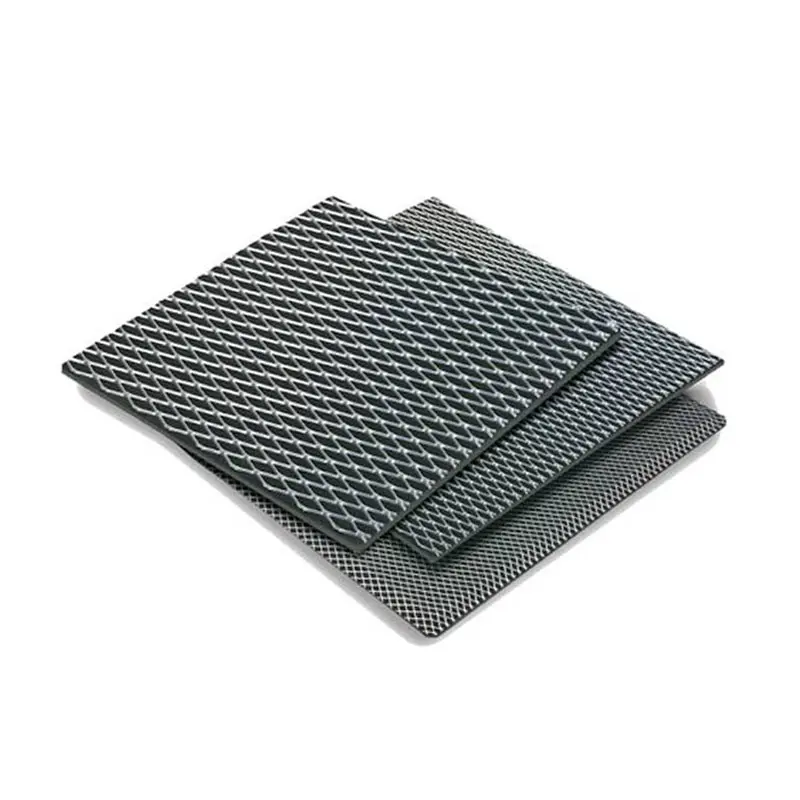

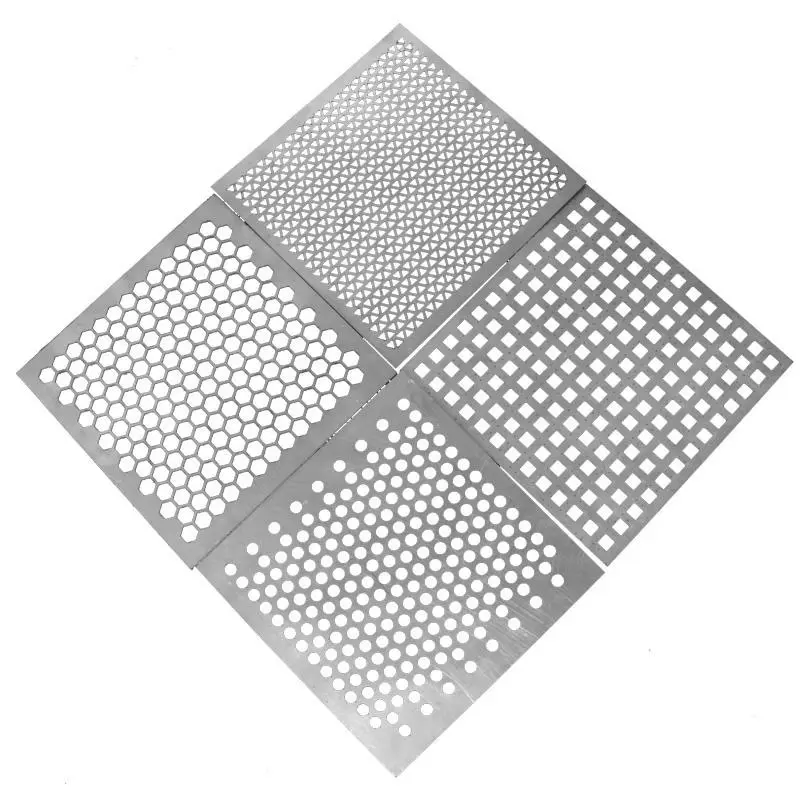

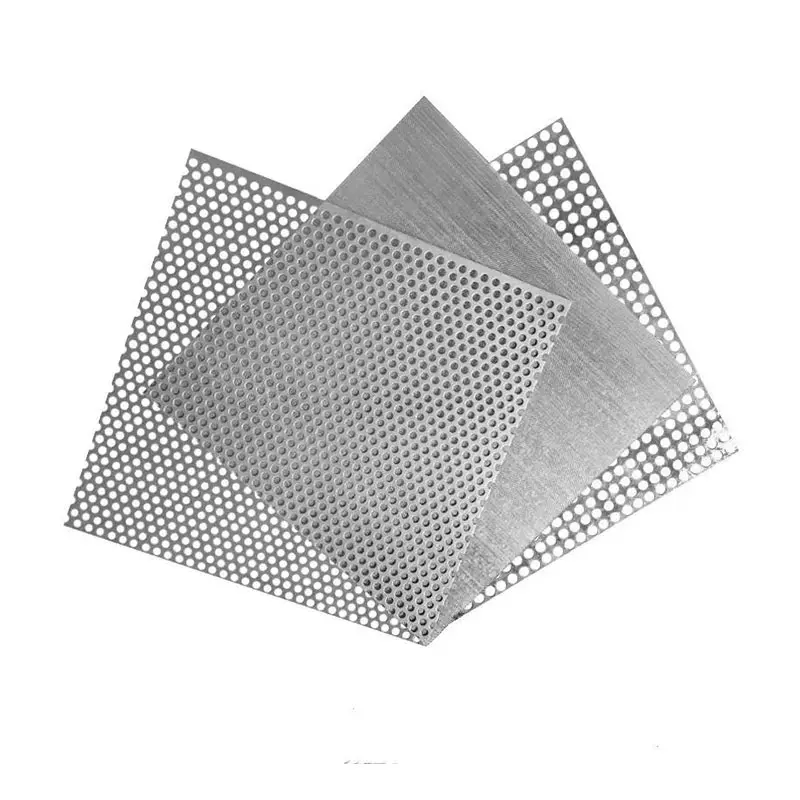

Stainless/Carbon Steel Metal preforated mesh

Shandong Rigang Supply Chain Management Co.,Ltd. Punching mesh/Perforated mesh refers to punching holes of different shapes on the same material. Common raw materials for perforated mesh include cold-rolled steel coils, stainless steel, galvanized steel coils, aluminum coils, copper coils, etc. Perforated mesh is suitable for environmental noise control, sound-absorbing panels around buildings, generator rooms, etc., and can also be used as speaker grilles.

The perforated net has a lot of loss in the production process, and the production process is complicated, mainly because it has a lot of hole-like structures, but this variety of shapes adds a colorful visual impact to the perforated net. Make the decoration effect of the punching net more obvious. At the same time, the perforated mesh has good air permeability and a wider range of use.

Specification of punching mesh plate: aperture 0.2-20mm, plate thickness 0.25-20mm

Iron plate punching mesh is divided by thickness: 1, thin plate, 2, medium plate, 3, thick plate, 4, extra thick plate

Iron plate punching mesh is divided into: 1. Hot rolled steel plate, 2. Cold rolled steel plate material, 3. Stainless steel plate 302, 304, 316, 304L, 316L, 4. Aluminum plate, and 5. Copper plate.

+86 18865111877

+86 18865111877